Zero Liquid Discharge

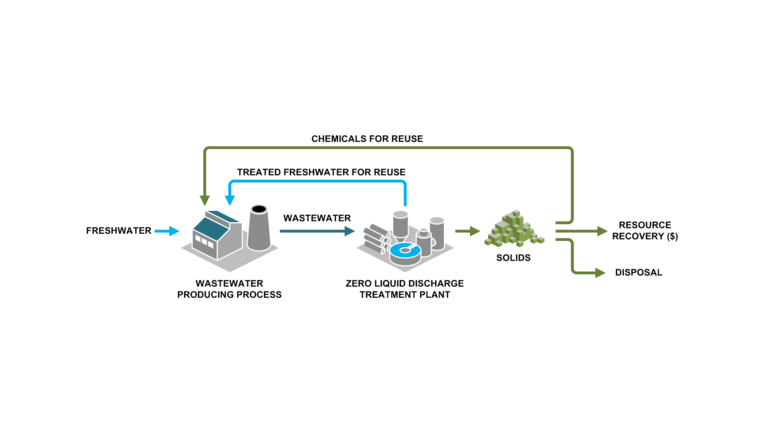

A Zero Liquid Discharge (ZLD) system involves a range of advanced wastewater treatment technologies to Recycle Recovery and Re-use of the ‘treated’ wastewater and therby ensure there is no discharge of wastewater to the environment.

A typical ZLD system comprises of the following components:

1. Pre – treatment (Physico-chemical & Biological) 2. Reverse Osmosis (Membrane Processes)

3. Evaporates &Crystallizer (ThermalProcesses)

Efficient, innovative management of entire water cycle for industrial application are heading towards Zero Liquid Discharge (ZLD), allowing businesses to save money, reduce environment impact and meet pollution discharge.

Achieving stringent wastewater treatment regulation and reducing water usage have become one of the most critical considerations in industry today. Numerous environmental regulations, rigorous permitting processes, and lack of water availability, among other factors, are driving many industrial facilities to implement zero liquid discharge (ZLD) systems as a solution.

Key Benefits of ZLD

- Recovers valuable ingredients from effluent wastewater

- Reduces process water disposal cost

- Meets environments permit target

- Reliable and robust solutions allows focus on main production business

In many cases, your plant’s water consumption can be reduced by up to 90 percent – saving money and helping to protect the environment. With more than 10 years of experience in the design, delivery, commissioning and service of ZLD systems.wws provide a comprehensive portfolio of technologies for ZLD applications,

including brine concentrators, evaporators, and crystallizers.

ZLD equipments, such as ultrafiltration (UF), reverse osmosis (RO), and Evaporators to provide the optimal solution. Our specialists can tailor a system to fit your wastewater characteristics, flow rates, and end-product requirement.

ZLD evaporator systems for concentrating liquid waste streams allow you to recover distilled water from waste streams.

Crystallizing systems for ZLD reduce wastewater discharge and, in many cases, can allow you to capture valuable by-product. Typically an evaporator or RO (Reverse Osmosis) system is used to pre-concentrate Waste water. Crystallization or evaporation then produces water for reuse as well as recovering specific salts that are suitable for disposal or resale to offset plant costs. We also provide parts and service on all of our equipment, as well as equipment which may have been provided by other manufacturers.

Application Area

- Textile Industries

- Distilleries PharmaIndustries

- Chemical Industries

- Paper Industries

- Tannery Industries

- Dye & Dye Intermediaries

- Edible Oil Refineries

- Electroplating Industries

- Sugar Industries